In the precision engineering industry, machines have to be so accurate that mechatronic design is a prerequisite. In fact, precision engineering was the first industry where mechatronic design was widely adopted in the early 80’s. In mechatronic design, mechanics and electronics are not designed in their own silos, but coupled, using modeling and simulation. The technique is used for a wide variety of machines and components:

- XY-stages

- robotic manipulators

- linear motors

- servo motors

- vacuum systems

Modeling and simulation for precision engineering

20-sim is an excellent tool for the design and testing of components in precision engineering. Typical applications are:

- Model electric drives using the components of the Electronics library.

- Model linear stages and drives using the Mechanics library.

- Model mechanical linkages using the 3D Mechanics editor.

- Use PID controllers from the Signals library.

- Design control systems using Controller Design.

- Simulate your models and inspect the results.

- Visualize results using 3D Animation.

- Analyze your system using the Frequency Domain.

- Optimize your system using the Time Domain.

- Export models as C-code.

- Advanced system design using the Dynamic Error Budgetting Toolbox.

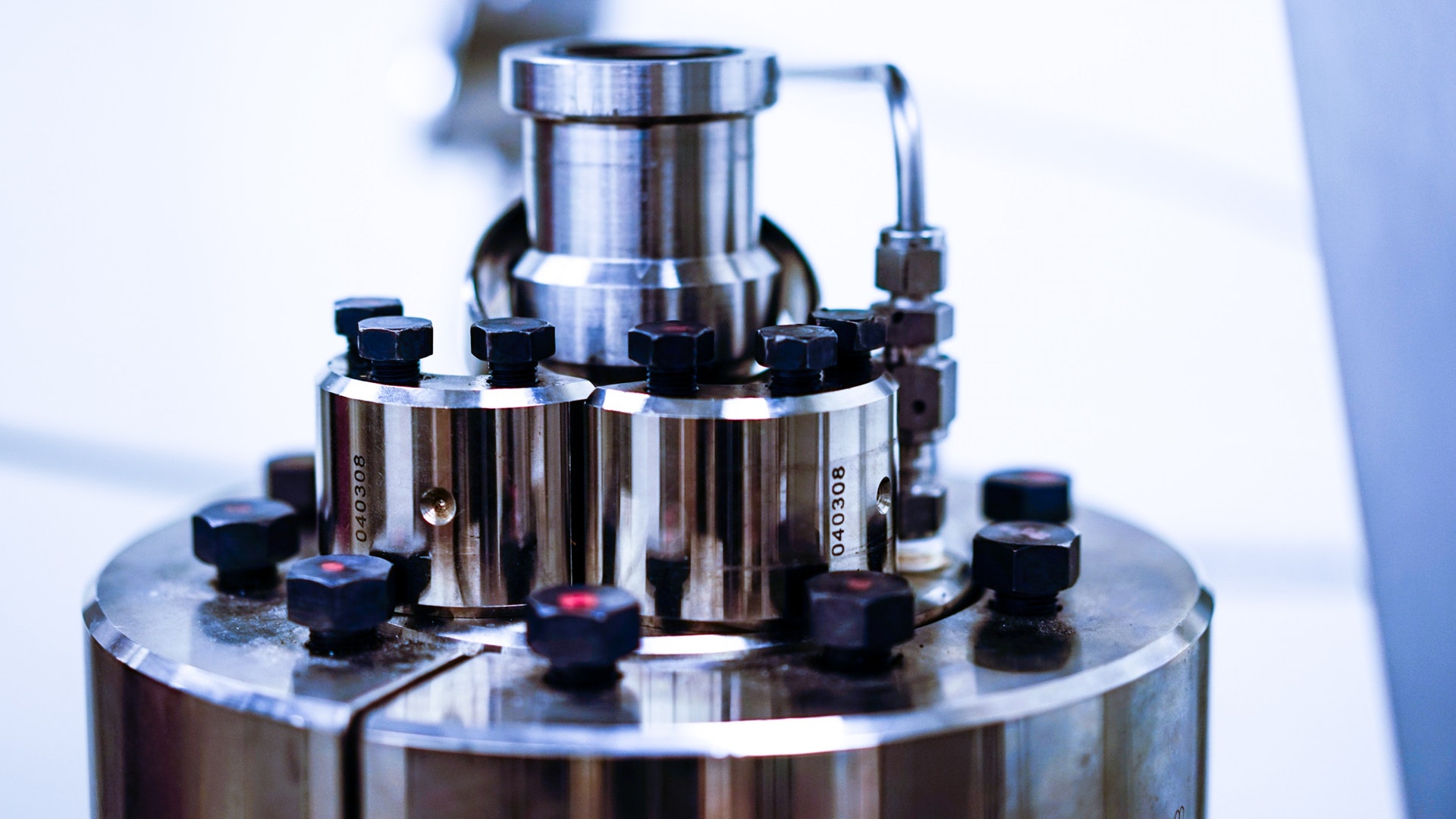

Example: Machine Support Frames

The Dutch company MECAL designs, produces and installs Machine Support Frames (MSF’s) for the semiconductor industry. An MSF frame has to provide a stable, elevated base for the production machine that is placed on it. Normally an MSF is rigidly connected to the fab floor. This results in the same low vibration levels as on the fab floor as well as a very high stiffness for (inertial) forces generated by the machine.